Do you know the ultimate purpose of calibrating a pressure gauge? It is to confirm precise readings. With time, the precision of a pressure gauge may deteriorate due to several aspects. This includes wear and tear, contact with temperature levels, and mechanical shock.

When a pressure gauge isn’t calibrated during testing, it could produce incorrect readings. This led to safety risks for people involved in work tasks and damage to the equipment. Plus, expensive production mistakes happen quickly. This may go unnoticed because no regular checks were done on this device.

When you calibrate a pressure gauge, it helps to confirm its accuracy and reliability. You can Pressure Gauge Calibration Services also make the required modifications to guarantee it functions correctly.

When Should I Calibrate the Pressure Gauge?

Experts say that pressure gauges should be calibrated every 6 to 12 months. But, it can change depending on how frequently you use it and the kind of environment. Certain events may show an instant need for calibration. For instance, dropping the gauge, exposing it to temperature levels, or unusual readings. Moreover, whenever a gauge gets repaired, it needs recalibration to ensure precision.

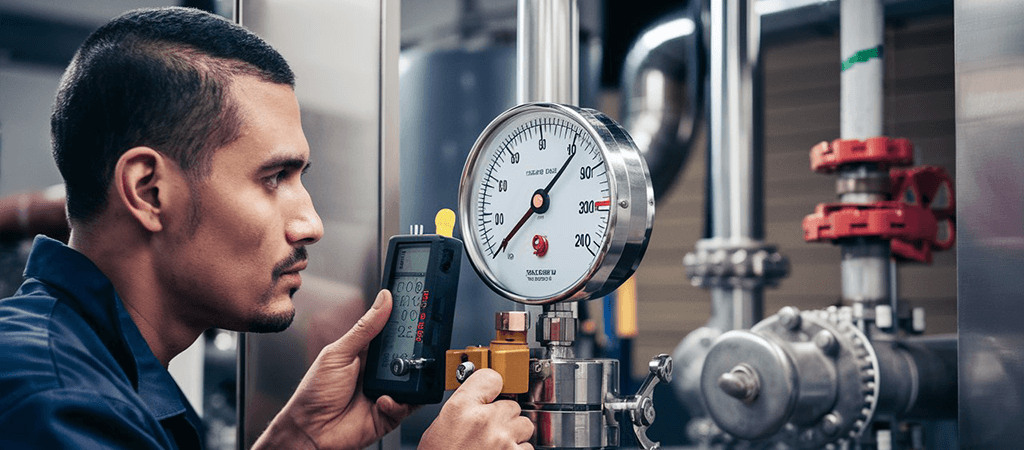

How do you Calibrate your Pressure Gauge?

Calibrating a pressure gauge means you compare it to see if it meets a traceable standard. One can also make changes as the readings are precise and dependable.

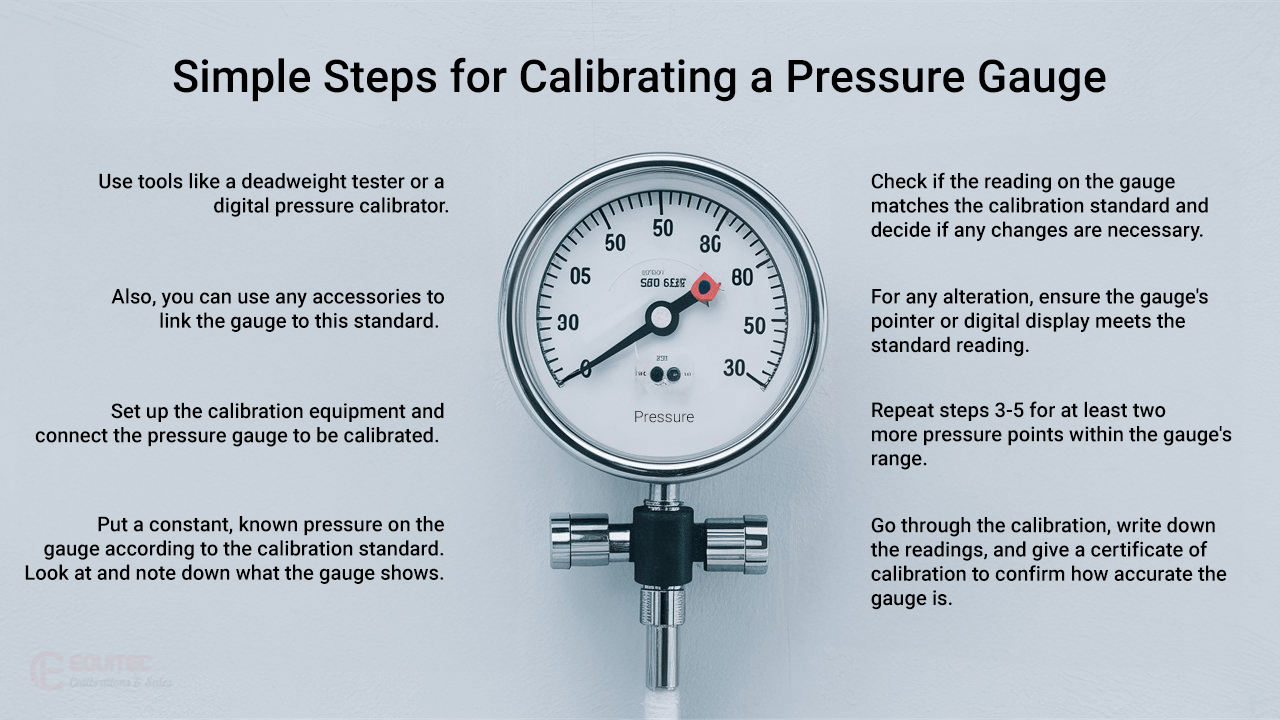

Here We Share Simple Steps for Calibrating a Pressure Gauge:

- Use tools like a deadweight tester or a digital pressure calibrator. Also, you can use any accessories to link the gauge to this standard.

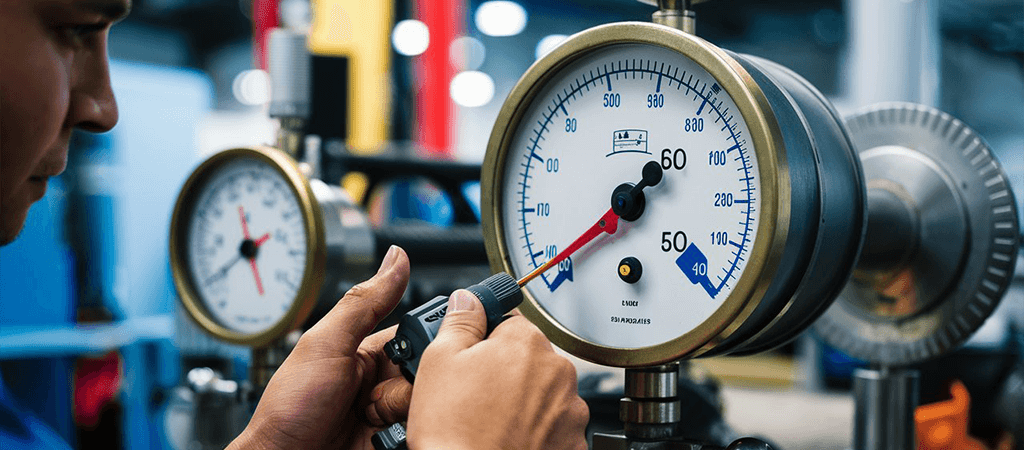

- Set up the calibration equipment and connect the pressure gauge to be calibrated.

- Put a constant, known pressure on the gauge according to the calibration standard. Look at and note down what the gauge shows.

- Check if the reading on the gauge matches the calibration standard and decide if any changes are necessary.

- For any alteration, ensure the gauge’s pointer or digital display meets the standard reading.

- Repeat steps 3-5 for at least two more pressure points within the gauge’s range.

- Go through the calibration, write down the readings, and give a certificate of calibration to confirm how accurate the gauge is.

One should know that pressure gauges when calibrated, need to be calibrated differently. You may need temperature adjustments or many adjustments for pressure ranges. It is better to adhere to the manufacturer’s instructions.

How Frequently Should a Pressure Gauge be Calibrated?

The number of times pressure gauge calibration is needed depends on different elements. These include:

- How precise is the process required to be?

- What kind of environment does the gauge work in?

- Suggestions from its manufacturer?

According to some industry norms, a pressure gauge should be calibrated every year. But others may suggest short or long periods, depending on the use of this equipment.

It is advised to adjust pressure gauges annually or more often during tough situations. This includes strong vibration, a different temperature, or contact with substances that corrode. Frequent calibration ensures that your gauge is accurate and offers precise readings. This is crucial for maintaining the quality of products, the effectiveness of procedures, and safety.